Platinum ID

Double Jacket PU Lined Attack Hose

Lightweight attack hose built for carry-up and high-pressure nozzle operations.

- ALL-POLYESTER DOUBLE JACKET

- POLYEUROTHANE (PU) COATED REVERSE TWILL LINER FOR LOW-FRICTION FLOW

- CERTIFIED FOR MILITARY AND INDUSTRIAL APPLICATIONS

- ENGINEERED FOR HIGH-PRESSURE AND MULTI-NOZZLE USE

Our proprietary mechanical coating process increases abrasion resistance by up to 3x compared to standard treatments. This finish enhances heat and flame resistance, minimizes water absorption, and provides exceptional durability against petrochemicals, bacterial growth, and mildew.

The jackets shall be evenly and firmly woven, free from unsightly defects, dirt, knots, lumps, irregularities or twist that might affect the serviceability of the finished product. Each jacket shall be seamless and shall have polyester filler yarns woven around the hose throughout its length, with the warp ends interwoven with the warp yarn covering the filler yarns. Warp ends of both the inner and outer jackets shall be spun staple polyester developed, designed and processed for the fire hose jacket warp yarns. The use of nylon, polyamide, or rayon yarns used in the warp or filler direction is not allowed. The use of any warp yarns of filament or entangled construction is expressly forbidden. Filler yarns of both the inner and outer jackets shall be high-tenacity filament polyester developed, designed, and processed for the fire hose jacket filler yarns. These filament polyester yarns shall be free from defects that are unsightly or may affect the serviceability of the finished hose. The ring spun polyester warp ends must completely cover and protect the filament polyester filler yarns. The inner jacket shall be of reverse twill weave, to allow for a smooth waterway. The jackets shall be constructed with a high pick count “anti-whipping” design exclusive to MaTex Hose.

The adhesion shall be such that the rate of separation of a 1½” strip of lining, transversely cut, shall not be greater than 1” per minute under a weight of 18 lbs. No Exceptions. Thickness of liner and adhesive shall not exceed 0.025”

The lining shall be a single ply extrusion of ether-based, super high tensile polyurethane, highly resistant to electrolysis, creating a thin wall surface to reduce weight for the total hose length. Minimum tensile strength shall be 7000 psi on a 1 1/2” strip. MaTex Platinum carries a lifetime warranty against liner delamination. The lining meets NSF-61 for potable water use.

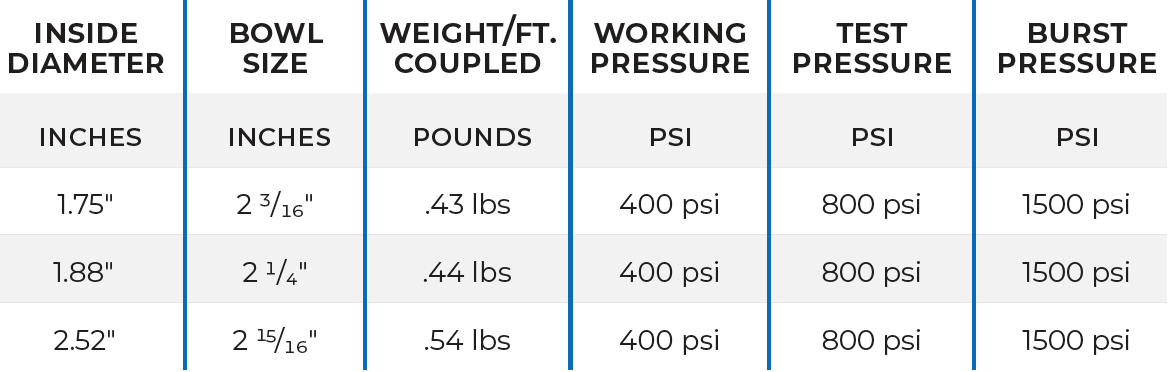

Hydrostatic tests shall be conducted on hose equipped with the couplings to be delivered in accordance with NFPA 1961. Each length of hose is to be subjected to a hydrostatic proof test pressure of 800 psi for at least 15 seconds and not more than 1 minute. Higher test pressures which may weaken the hose are expressly forbidden. Twist: The hose shall not twist more than 4-1/4 turns per 50 ft. for the 1¾”size, and not more than 1 ¾ turns per 50 ft. for the 2½” size under a pressure of 800 psi. No final twist in a direction to loosen the couplings shall be permitted.

The hose shall be capable of performing in sub-zero conditions. A 3-foot section of hose shall be exposed to a temperature of -65 F for a period of 24 hours. At the end of the exposure period, and while maintained at the -55° C exposure temperature, the hose shall be rapidly bent 180° double on itself, first one way and then the other. There shall be no cracking or breaking of the jacket or liner. Leakage shall be cause for rejection.

A 3-foot sample of hose chosen at random shall stand without failure a hydrostatic pressure of 1500 psi while lying straight or curved on a 27” radius. Retention of the coupling to the hose shall equal or exceed the burst pressure.

The hose shall not warp more than 20” from a straight line drawn from center to center of the fittings at the ends of the hose, and the hose shall not rise from the table.

A full length shall withstand, while kinked, without failure, a hydrostatic pressure of 500 psi.

The expansion in circumference of the hose between 10 and 800 psi shall not exceed 8%.

The elongation between 10 and 800 psi shall not exceed 8% for the 1½, 1¾”, 2” and 2½” sizes, and shall not exceed 10% for the 3” size.

WARRANTY INFORMATION

The fire hose furnished under the terms of this proposal has a potential service life of ten years, barring mistreatment or accidental damage that would render the hose ‘unfit for service.’ MaTex warrants the hose to be free from defects in materials and workmanship for a period of ten years. This warranty shall provide for the repair or replacement of hose and couplings proven to have failed due to faulty material or workmanship.